Now, in 2019, collaborating with our preconstruction department, we’ve exceeded this mandate by implementing this model-based process across all jobs under $30 million that require VDC services.

As a result, this process has set a new model-based shop drawing production standard for our trade partners and intrinsically drives success of past, present, and future scalable design build projects in the New England’s VDC department.

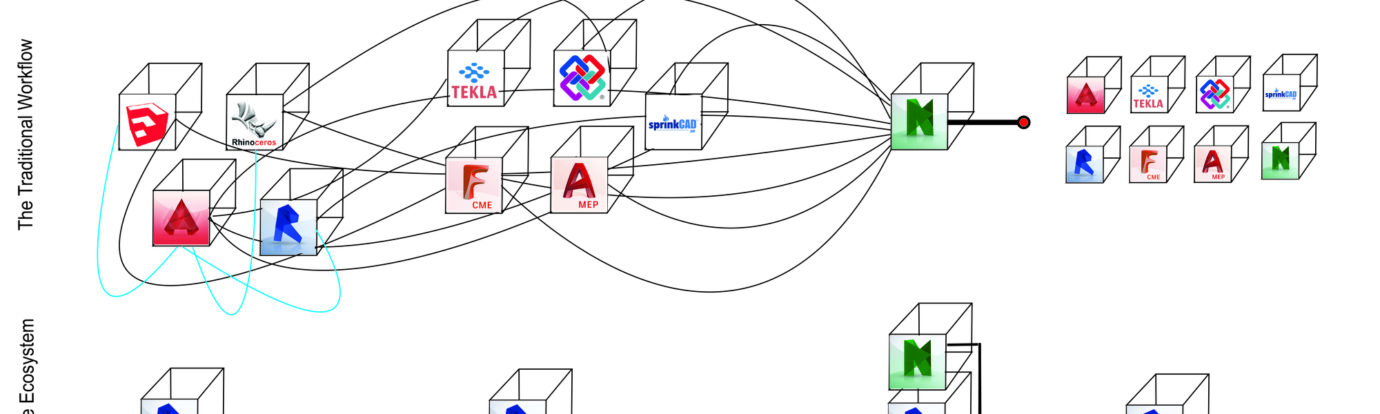

The Complexity of the AEC Industry

As more and more fast track and design assist/design build delivery methods are employed we have noticed decentralized document control and engineering scope gaps that needed to be addressed in a “smart” process specifically during shop drawing productions. Additionally, we found that the saturation of software platforms among our trade partners used for shop drawing generation alienated project-first success mentalities. The diagram above is typically the process by which most projects encounter; a single ecosystem seeks to clarify the process. Ultimately, we felt that there was an opportunity to increase the effectiveness of translating the complexity of today’s contract documents into shop drawings through a specification of means and methods.

Effective Means and Methods & Consequences

In order to do this, we re-built our Building Information Model (BIM) execution plan backwards from the AGC (Associated General Contractors of America) LOD – (Level of Development Specification for Building Information Modeling) with the intent to specify the means and methods of how our trade partners achieved their end goal of shop drawings. In order to gain the control that we lacked with each trade in different platforms, we selected a platform/ecosystem capable of addressing our trade partner’s individual needs while prioritizing the goals of the project. The criteria we sought out for our single ecosystem included: an ability to leverage the AE industry standard of modeling, a standardization protocol for high quality documentation, better accessibility for VDCs teams to manipulate & track, a substantial vehicle for centralized “smart” information parameters, and a one-to-one translation of Facilities Management (FM) BIM. As a result, many consequences occurred:

- Increased effectiveness of each VDC engineer in New England

- Compression of our front-end draw/shop drawing durations and back-end FM data population

- Development of high-resolution schedule tracking

- Increase of shop drawings quality and RFI backup drawings

This approach leverages a highly effective shop drawing process that is embedded in a single ecosystem platform. By defining new of success, it has immensely positive contribution value to Design Assist/Design Build project deliveries within large and small project scales at Gilbane.