Understanding the needs of, and working collaboratively with our clients and design team, the plans should be implemented early on and the project team should work to identify areas for this style of construction that will provide the greatest impact.

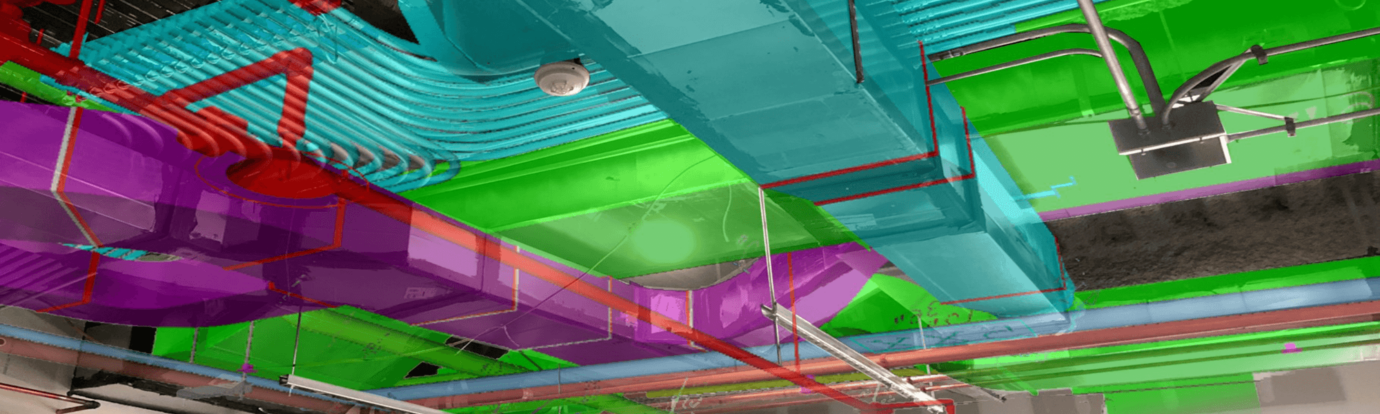

For instance, repeatable conditions in a project design are typically good candidates, and in our experience this specifically includes bathroom pods, exterior walls, headwalls, foot walls, sink walls, charting stations, mechanical, electrical & plumbing racks in the corridors and operating room ceilings.

Conditions will vary depending on the specifics of each project. We typically invite various trades during the preconstruction phase of the project to assist in development of the BIM model and obtain shop drawings for critical equipment.

Time & Safety Benefits

Skilled trades are reporting that they must find ways to alleviate the challenges of delivering a quality product with a shorter timeline. Prefabrication is an alternative solution to mitigate many of these issues. This technique allows for the building components offsite, when trades would otherwise be waiting for the onsite building to progress, which saves time of our skilled trades. There are benefits to the client as well as we have seen a 35% reduction in the overall timeline in our Southeast hospital prefabrication projects. The speed-to-market timeline allows the facilities to open earlier, which makes for a higher return of investment for the owner. Most importantly there has been improvement of safety for our on-site trades, Gilbane has had zero lost time injuries with that included over 200,000 manhours. Finally, as another time and schedule saver, we calculated over 16,000 manhours off-site on a recent project reducing trade stacking.

Quality

On projects where we have utilized prefabrication, we typically see zero RFI’s related to project routing or coordination. The extensive detailed organization of BIM-coordinated prefabricated assemblies contributes to the schedule savings by eliminating issues before they become a problem in the field. An additional benefit is the improved quality since building assemblies in an offsite facility provides ideal conditions that are typically in a non-critical phase of the project. This allows us to focus on quality and if needed, the repair of quality issues before being shipped to the site.

Although prefabrication may not be the answer for every building, we have seen significant improvement of our project metrics. With this style of construction, we have seen the project from conception to completion with high quality, low safety issues, and a speedier timeline. Our experience dictates that you should consider prefabrication as a strategy with your stakeholders and team early on to see if this technique could save time, money and improve the quality of your project in the end.

One Reply to “Prefabrication as a Project Strategy”

Raghuvaran Chakkravarthy

Prefabrication materials/panels made a big difference in safety. Prefabrication and modular construction helps us to plan accurately especially on safety with all the subcontractor partners on-field.

Comments are closed.