How is 3D printing used in construction?

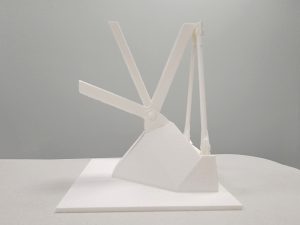

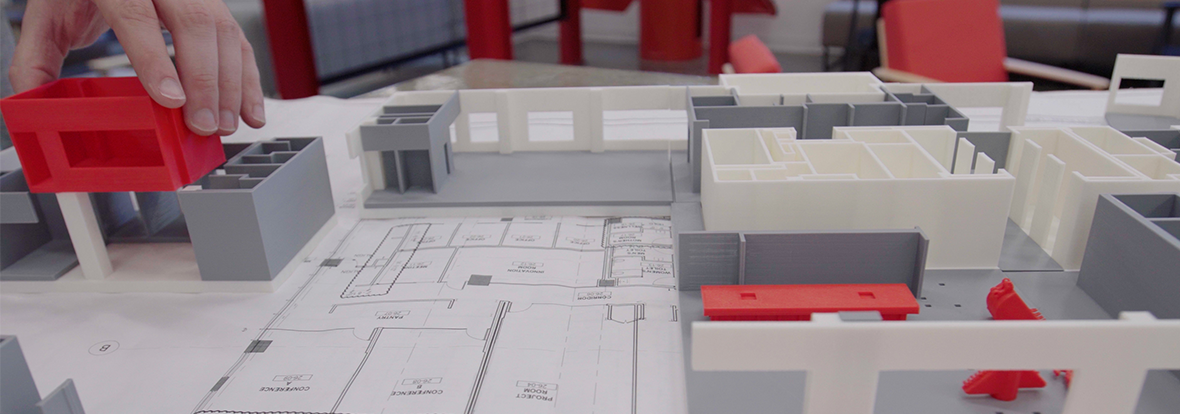

The advent of 3D printers has helped catapult the construction field into a whole new era of technological innovation. Creating models of planned construction projects is extremely helpful to engineers, architects and other contractors when trying to visualize the result of a building. However, they typically take several weeks to complete, which can significantly delay the progress of a project. Creating a physical building model gives our clients and design partners a better visual understanding of the project. For example, using 3D printing technology, the 3D model of Lamar High School took only 12 days to create, when previous methods would have taken at least 3X as long.

A lot has changed since we last wrote about 3D printing (Creating Something Out of Thin Air: 3D Printed Models). Although prints may look similar from a few years ago, they have grown in scale and complexity over time.

Printing Peer Group

At Gilbane, our Virtual Design and Construction (VDC) 3D Printing Peer Group collaborates during quarterly meetings to share methods and applications. With about 40 members, the team continues to be at the forefront of innovation. At this year’s annual November meeting, the group will discuss moving to a more operation-driven printing to deliver more prints out to our jobsites. This approach involves printing mock ups, details on plans, and more complex phasing for jobs. Our prints are now telling a story to those viewing it.

3D Printing for COVID Response

When the COVID pandemic broke out, Gilbane’s 3D printing peer group brainstormed how they could help support relief efforts and front-line workers. They used a model produced by the Czech ministry of health that could be tweaked and printed for use as a face shield in cases where additional protection was needed.

They began to move forward with this model as well as “ear savers” which would relieve the strain on ears from constant mask wearing. Within a matter of days, a group who had access to a 3D printer were willing to volunteer time on top of work to get the goal accomplished. The first batches of prints were completed and out the door within a week as they printed as many as possible with the materials on hand. After roughly two months of work, the industry had recovered enough to receive larger shipments from manufacturers. The final statistics truly remarkable”

- Over the course of 9 weeks from early April to mid-June – when mass production alternatives were non- existent, the team produced and distributed nearly 800 items

- As a group, over 200 hours of time were volunteered on top of accomplishing work tasks

- Between all the hard- working printers, roughly 5200 hours of printing took place

Additionally, our VDC team saw the opportunity to utilize existing resources to 3D print face shields for local healthcare personnel. They obtained medical-grade filament that can withstand decontamination efforts to print the forehead and chin straps. Each print takes about eight hours and can produce up to eight parts. Running multiple machines from home, the team donated over 200 shields to local healthcare workers.

The pros of 3D printing are still constantly developing as the challenges present themselves. With that being said, the biggest pro to 3D printing is speed to product. For example, once modeled, a set of 8-12 face shields could be produced in under 24 hours. Another advantage is the versatility. Not only does the user can produce anything that is modeled properly, but when the need was felt to provide aid to our healthcare heroes, as a group we were able to test a newer filament type and provide best practices for printing in a matter of days. This filament was best suited for the medical world with its resistance to chemicals, toughness, heat tolerance, and its common use in production of medical supplies.

We primarily leveraged the materials available to us, eliminating the need for special resources. With supply chain issues from COVID impacting many items, the flexibility of using already available materials made 3D printing the best option. We can’t wait to see what the future holds for 3D printing.

One Reply to “3D Printing: What You Should Know”

Hunter Hayes

I think its fantastic you’re team is leveraging scale 3D printed models to visualize complex phasing of the jobs!

Comments are closed.