With the support of Associated General Contractors of America (AGC), LCI, and Dodge Data & Analytics, a new survey for contractors has launched to gather insights and data regarding how Lean practices positively impact construction management and can help overcome these challenges.

Lean Perspective

Five years ago, I was honored to give a TED talk at the AGC National Convention about my Lean journey. As I was sketching out my thoughts, I realized my expedition began as a small child where I received star charts for weekly chores that resulted in incentives for favorable performance. Fishing trip preparations were outlined with an end milestone in mind. Lean practices seemed to be engrained into my way of life by the time I entered the construction workforce as a superintendent.

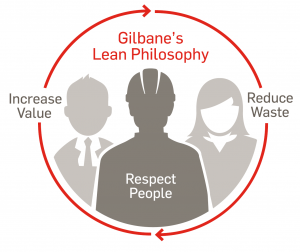

From day one, I was instinctually looking for ways to eliminate waste. ‘Plan, Do, Check, Adjust’ was just the way I conducted business. So when I stumbled upon the Lean Construction Education Program, it was an easy sell for me to enroll in the program and earn my Certificate of Management-Lean Construction (CM-Lean). As someone who gravitated so naturally to the Lean way of life, it was equally difficult for me to understand why others didn’t. I engaged my trade partners and peers across the industry and asked “why” as many times as people would tolerate. The root cause appeared to be a lack of understanding coupled with a lack of proof. People wanted data and statistics that proved making a change in the way they had always done things would result in favorable outcomes.

From day one, I was instinctually looking for ways to eliminate waste. ‘Plan, Do, Check, Adjust’ was just the way I conducted business. So when I stumbled upon the Lean Construction Education Program, it was an easy sell for me to enroll in the program and earn my Certificate of Management-Lean Construction (CM-Lean). As someone who gravitated so naturally to the Lean way of life, it was equally difficult for me to understand why others didn’t. I engaged my trade partners and peers across the industry and asked “why” as many times as people would tolerate. The root cause appeared to be a lack of understanding coupled with a lack of proof. People wanted data and statistics that proved making a change in the way they had always done things would result in favorable outcomes.

The Challenge

I accepted the challenge and began researching. Unfortunately, I couldn’t find any significant findings that supported my cause from the contractor’s perspective. I did, however, find out that the LCI was in partnership with Dodge Data & Analytics in sponsoring an owner outcome study based on the business case for Lean Project Delivery. Survey results showed that projects using Lean methodology had a higher percentage of projects being completed ahead of schedule and under budget than those not using Lean. LCI followed up their research from the owner perspective by including designers in a study that compared best versus typical projects, as well as design firm-relevant metrics to establish a benchmark of performance to reveal the impact of Lean methods.

Surveying Contractor’s Perspective

These studies are the most widely quoted and utilized evidence-based tools that presenters, contractors, designers, owners, and other Lean enthusiasts utilize when conveying the value of Lean methodology. After seeing such promising results from both the owner and the designer perspectives, it made sense to pursue a third leg of this survey from the contractor’s perspective.

Teaming with AGC’s Paige Packard, we reached out to Bevan Mace, Vice President at Balfour Beatty, who had been a key contributor in both prior surveys. We also engaged AGC of America’s Lean Forum for initial brainstorming and preparation. Once the team’s proposal was accepted by AGC and Lean Construction Institute (LCI), we were off to the races.

Members from all three organizations worked together to provide the industry with evidence that utilization of Lean methodology provides benefits across the board for:

- Schedule

- Cost

- Safety

- Employee Engagement

- Client Satisfaction

After months of hard work, the final survey instrument has been completed. To take the survey, click here.

Sharing our Findings

So, if you find yourself in the position I was in early in my career, looking for proof that Lean is worth the investment, please join us in the Fall for some insightful research and hear about the findings for a business case for Lean construction from the general contractor perspective, which will be presented at both AGC National Convention and Lean Construction Institute Congress. Hope to see you there!